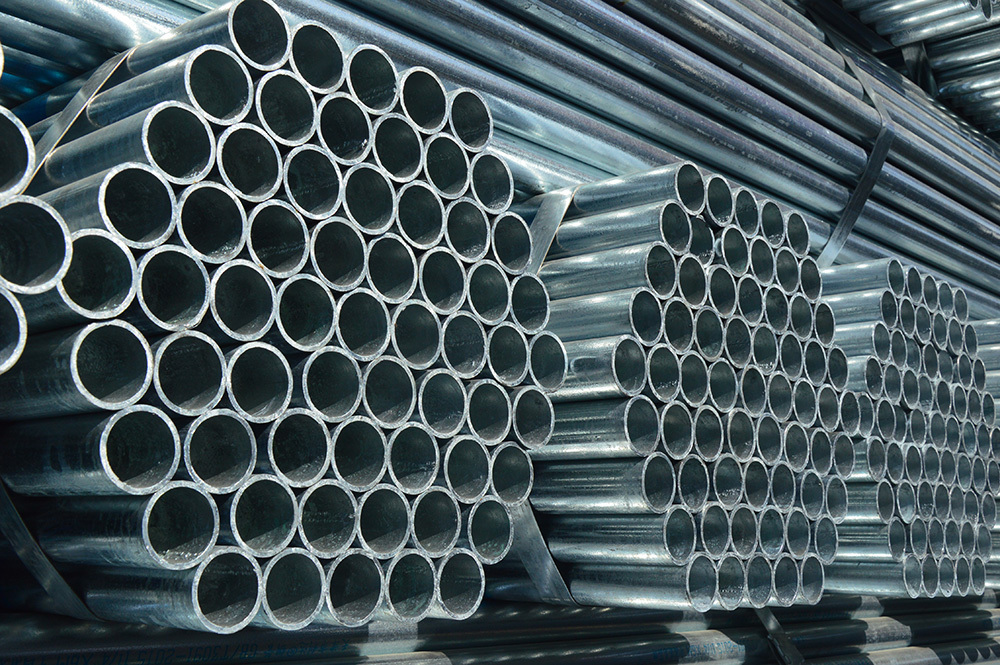

"Lida" brand galvanized steel pipe

Key words:

"Lida" brand galvanized steel pipe

Classification:

Product Introduction

Previous:

The next one:

Related Products

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!