Welded steel pipe

Key words:

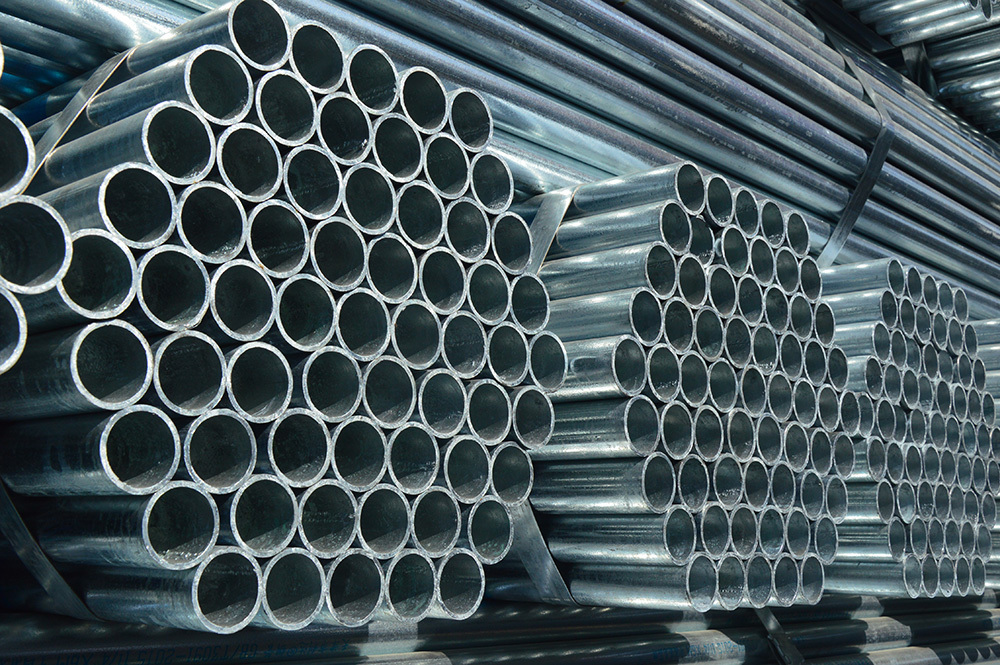

Welded steel pipe

Classification:

Product Introduction

Raw material coil - flattening - end cutting and welding - forming - welding - removal of internal and external weld beads - pre-correction - induction heat treatment - sizing and straightening - eddy current detection - cutting - hydrostatic test - pickling - final inspection (strict quality control) - packaging - delivery.

Features:

The production process of ERW pipes is simple, with high production efficiency and low cost, and has developed rapidly. The strength of spiral welded pipes is generally higher than that of ERW pipes, and can produce welded pipes with larger diameters using narrower slabs, and can also produce welded pipes with different diameters using slabs of the same width. However, compared with straight seam pipes of the same length, the weld length increases by 30~100%, and the production speed is lower.

Application range:

Products are widely used in water supply projects, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction.

Used for liquid transportation: water supply, drainage. Used for gas transportation: gas, steam, liquefied petroleum gas.

Used for structural purposes:

Used as pile pipes, bridges; piers, roads, building structural pipes, etc.

Previous:

The next one:

Related Products

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!